Polyester rope is a popular choice for a wide range of applications due to its durability, strength, and resistance to environmental factors. However, one question that often arises when considering polyester rope is whether it stretches. To address this question fully, we need to explore various properties of polyester as a material, how these properties impact the rope's performance, and the conditions under which it may or may not stretch.

Understanding Polyester Rope

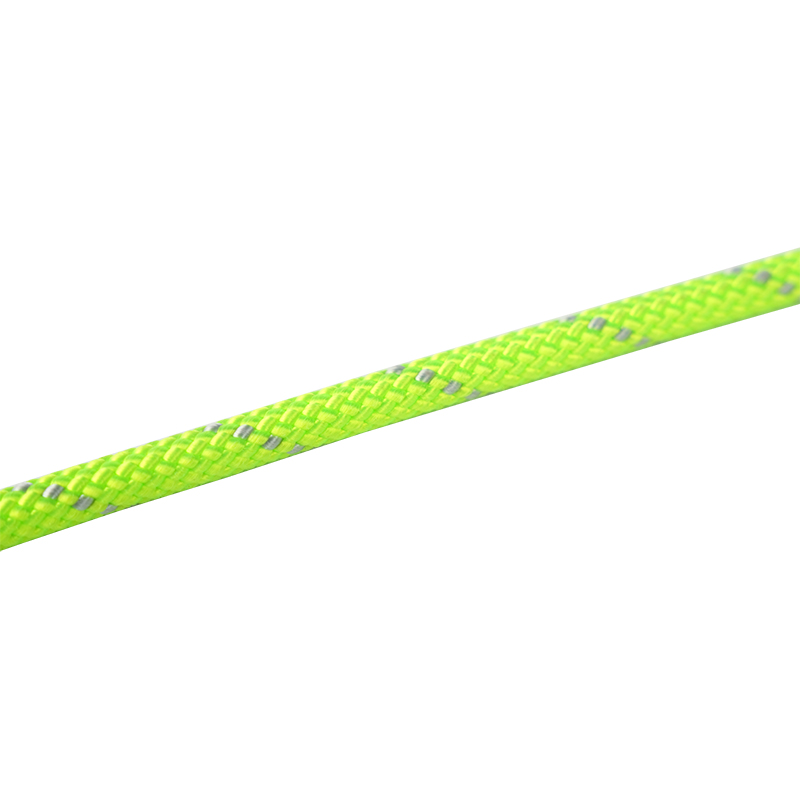

Polyester is a synthetic fiber made from a polymer known as polyethylene terephthalate (PET). It’s widely used in textiles, including ropes, because of its strength, resistance to UV rays, abrasion resistance, and ability to retain its shape over time. When polyester fibers are spun together to form rope, they create a smooth, flexible structure that can be used in a variety of applications such as marine, industrial, and recreational.

Stretch Characteristics of Polyester Rope

Polyester rope is often referred to as having low stretch compared to other materials like nylon. However, "low stretch" does not mean "no stretch." Understanding the factors behind polyester rope's stretch involves looking at both the rope's construction and the material's inherent properties.

1. Elasticity and Stretching Mechanisms

Stretch in any rope occurs when external forces, such as weight or tension, are applied to it. The elasticity of the material determines how much the rope will elongate under pressure. Polyester, due to its molecular structure, exhibits low elasticity compared to other synthetic fibers, such as nylon. Nylon can stretch up to 30% of its original length before it begins to break or lose its integrity, while polyester typically stretches only 10-15% of its original length. This means that polyester rope tends to maintain its form and doesn’t elongate as much under stress.

2. Construction of Polyester Rope

The way a rope is constructed can also influence how much it stretches. For example:

Braided Polyester Rope: Braided ropes, made by interlacing strands of polyester, often show minimal stretch. The braiding pattern helps distribute tension more evenly across the rope, and it’s less prone to elongation than a twisted rope.

Twisted Polyester Rope: Twisted ropes, on the other hand, may exhibit slightly more stretch than braided ones. The twisted fibers allow for a bit more movement between strands, which can lead to more stretching under load.

3. How Polyester Rope Handles Loads

The amount of stretch in polyester rope also depends on the weight or force applied to it. When subjected to small loads, polyester rope will stretch very little, offering minimal elongation. However, under heavy loads, some stretching can occur as the fibers are pulled apart slightly.

4. Temperature and Environmental Factors

Environmental factors like temperature, moisture, and UV exposure can affect how much polyester rope stretches. Polyester is well-known for its resistance to UV rays, making it more durable in outdoor conditions. However, extreme temperatures may impact its flexibility, causing the rope to stretch more under heat or become more rigid in cold conditions. High humidity or prolonged exposure to water can also influence the rope's stretch, though polyester remains fairly resilient in wet conditions compared to other fibers.

5. Comparison to Other Materials

When comparing polyester to other materials, its low stretch is one of the features that make it ideal for certain applications. For example:

Nylon Rope: Nylon has a much higher elasticity, which makes it better suited for applications requiring shock absorption, such as climbing ropes or tie-downs. However, this stretch can be a disadvantage in situations where maintaining a precise length is essential.

Polypropylene Rope: Polypropylene ropes have a similar low stretch to polyester but tend to be less durable and more susceptible to UV degradation.

Natural Fiber Ropes: Natural fibers like manila or hemp can stretch considerably more than polyester, which may not make them suitable for applications requiring high strength and minimal elongation.

Applications Where Low Stretch is Beneficial

Marine Use: Polyester ropes are widely used in marine environments for anchor lines, dock lines, and halyards. Their low stretch makes them ideal for applications where minimal elongation is required for safety, as they prevent excessive slack that could lead to unpredictable movements of boats.

Industrial Applications: Polyester ropes are commonly used in the construction, transportation, and manufacturing industries, where they are required to bear heavy loads with minimal stretching. This ensures that loads are handled securely without risk of the rope becoming too slack.

Rigging: In rigging, where ropes are used to control the movement of heavy loads, polyester's minimal stretch is an asset. Ropes used in this context need to maintain a consistent tension to ensure stability and control.

Rescue Operations: Polyester ropes are also preferred in rescue operations where precision and control are paramount. The low stretch ensures that rescuers can move with certainty without the concern of significant rope elongation.

Conclusion

While polyester rope does stretch, it does so far less than many other synthetic or natural fibers. This low stretch property makes it particularly useful in applications where stability and precision are required, such as marine, industrial, and rigging operations. However, under extreme conditions—like high temperatures or heavy loads—polyester ropes can exhibit some elongation, though they generally maintain their form better than other materials. Understanding the stretch properties of polyester rope helps users choose the right material for their specific needs, ensuring that they can maximize the strength and efficiency of the rope while minimizing the risk of unwanted elongation.