The inner core and outer skin of the 10mm 2200kgs nylon braided rope fit very well, and the feel is ...

The inner core and outer skin of the 10mm 2200kgs nylon braided rope fit very well, and the feel is ...

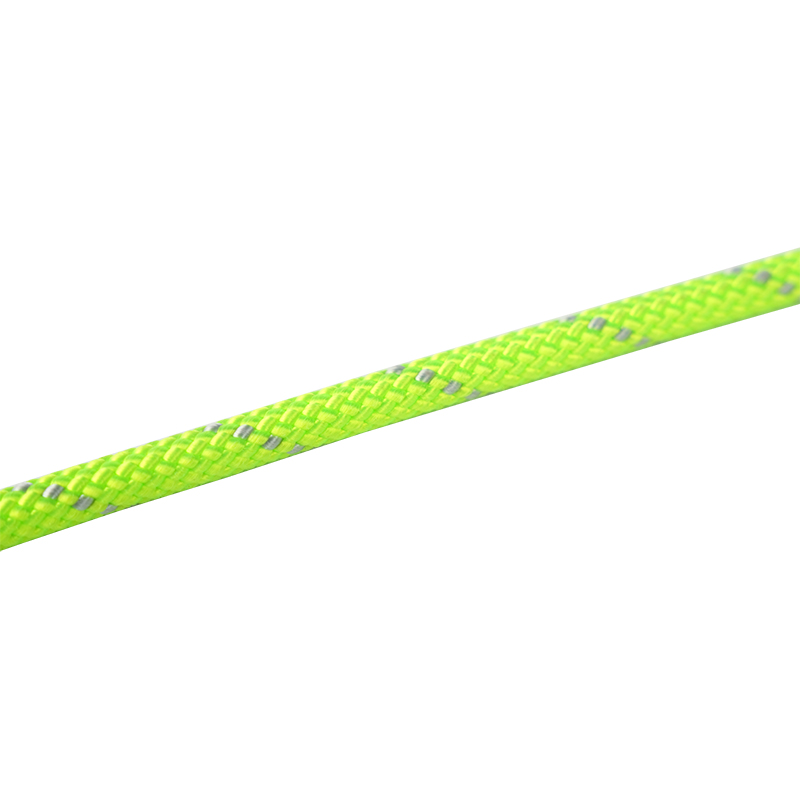

This 8mm wireless colorful nylon rope is crafted from premium nylon, combining high strength with ...

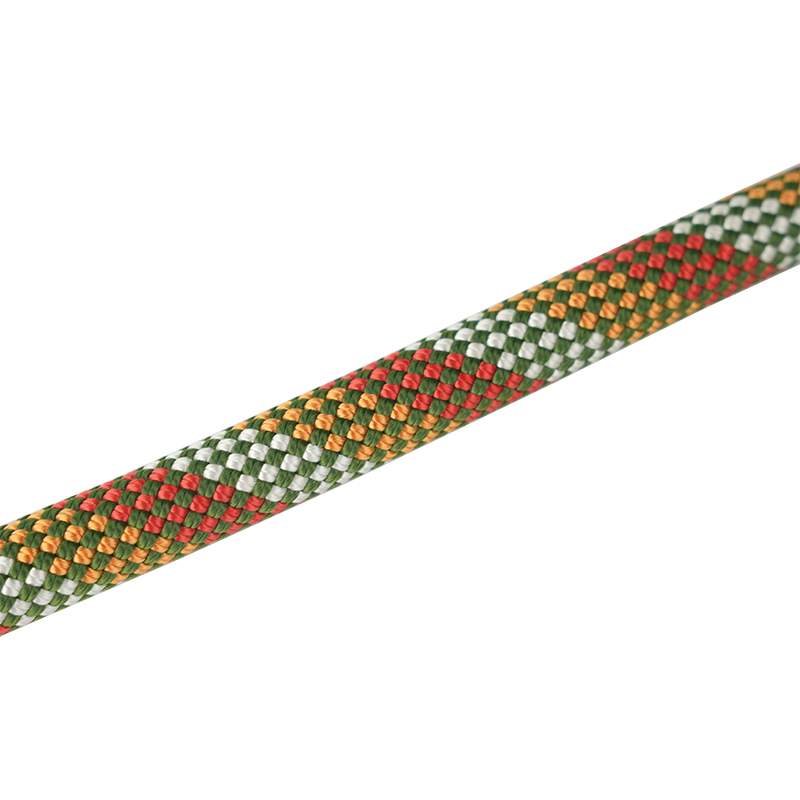

Crafted from high-strength nylon, this 12mm diameter rope is engineered for heavy-duty and complex e...

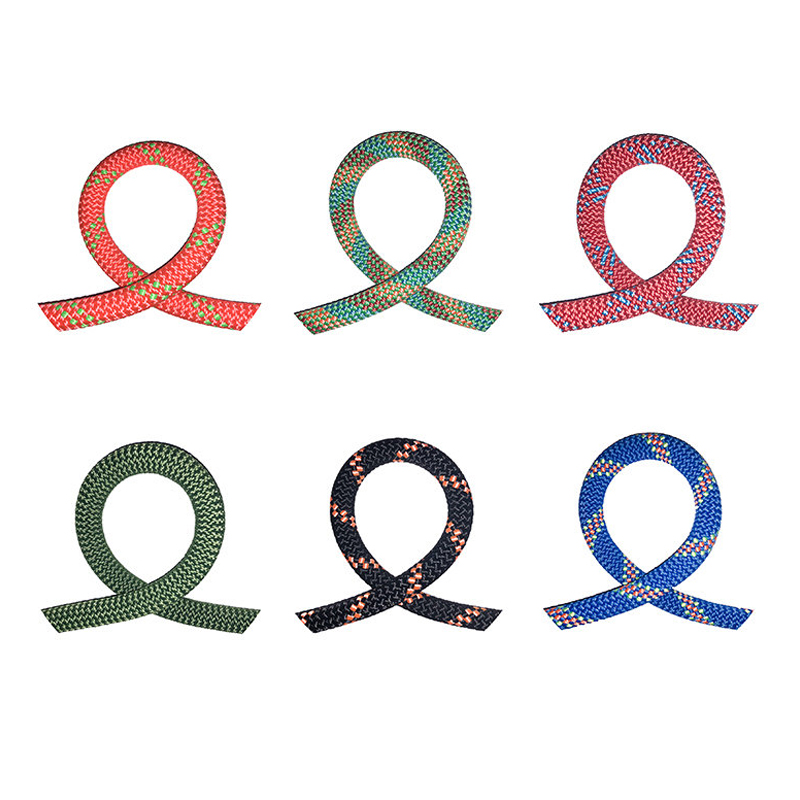

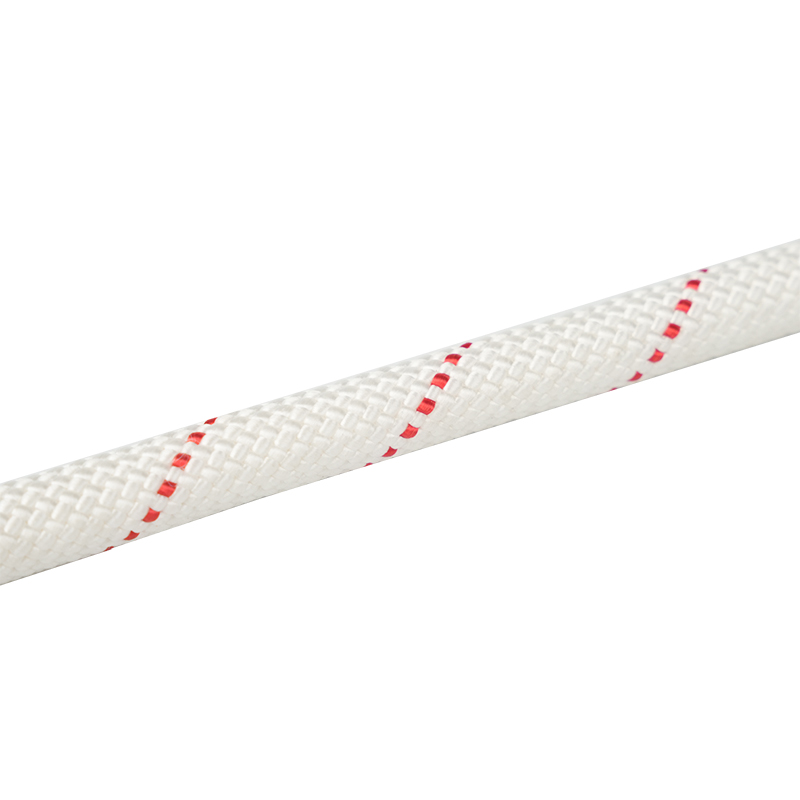

Material: polyesterDiameter: 10mmWeaving process: 48-strand diamond weaving, double-layer weaving ...

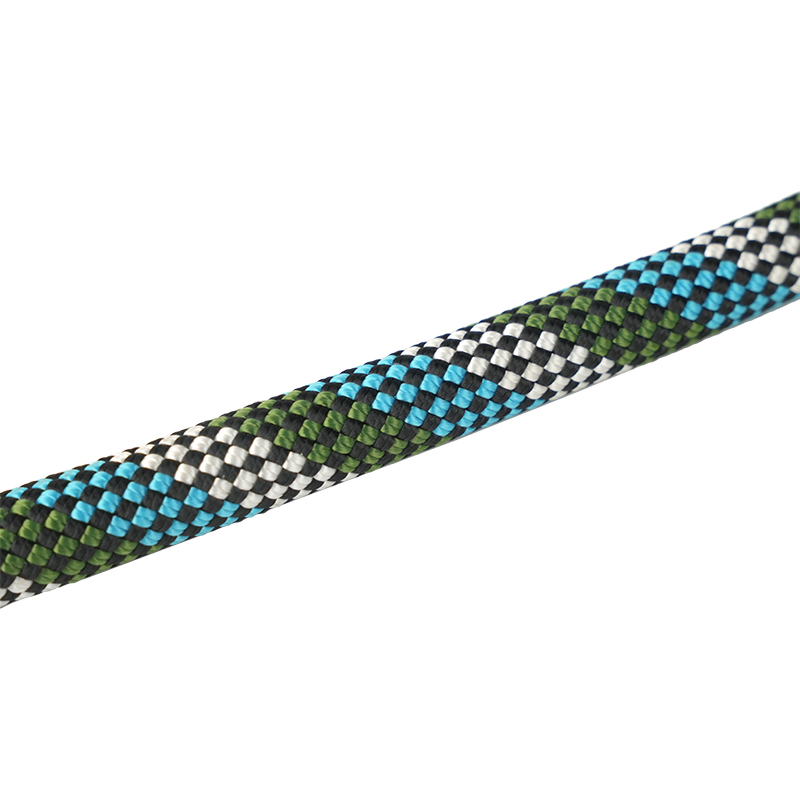

The 6mm fatigue-resistant polyester braided rope adopts a double braid design, which provides additi...

Crafted from high-density polyester fibers with dual-twist braiding technology, this 8mm rope featur...

Material: polypropyleneDiameter: 10mmWeaving process: 48-strand diamond weavingInner core: multipl...

12mm Lightweight Buoyant Polypropylene Braided Rope is made of high-quality polypropylene (PP) and i...

The 8mm white polypropylene braided rope is made of polypropylene (PP) and has high strength and wea...

This 10mm UHMWPE rope is highly strong and performs well. It can be used for water rescue, seawater ...

This aramid rope is mainly used in high temperature operations, special ships, electrical engineerin...

This safety rope is sound when working with heights plus it is a low stretch rope. Its diameter is ...

Taizhou KA Protection Products Co., Ltd. is located in the Taizhou Economic Development Zone, Jiangsu Province, China, with convenient transportation.

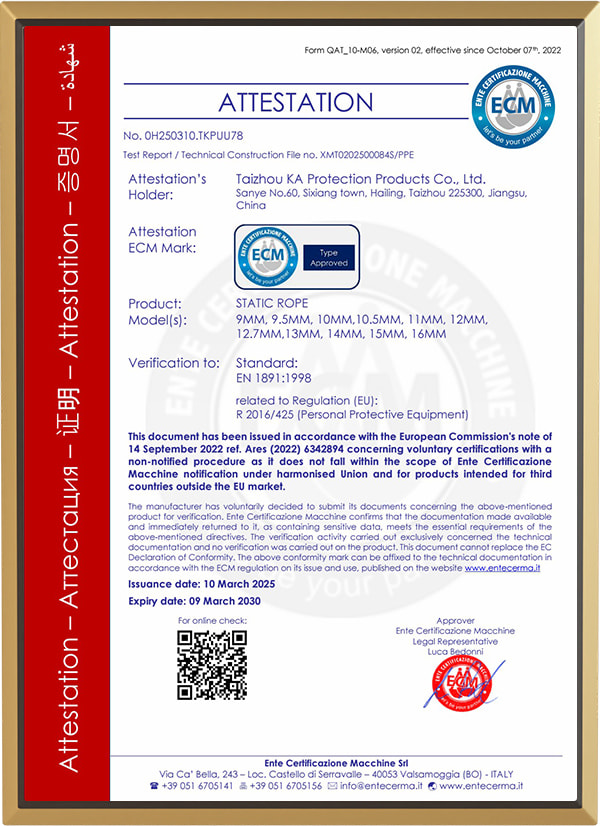

Since its establishment in 1986, the company has been dedicated to the production of safety harnesses, safety nets, safety ropes, and lifting slings. As Braided Rope Suppliers and Double Braided Rope Factory, our products are exported globally, including to countries such as the United States, Europe, Russia, the United Kingdom, South Korea, and Japan. Our products have undergone rigorous testing and have obtained international certifications, ensuring that each product provides crucial protection in critical moments.

The company's production strictly adheres to ISO standards, and each batch of products undergoes strict inspection to ensure quality. Supply Wholesale Double Braided Rope, Braided Rope for sale. Currently, the company covers an area of 5,600 square meters and has a construction area of 3,800 square meters, equipped with over 50 pieces of production equipment and comprehensive testing facilities, focusing on delivering safety protection solutions to customers worldwide.

For most climbers, single ropes are the best choice for sport climbing and straightforward multi-pitch routes, while half ropes excel in wandering alpine terrain and mixed climbing, and twin ropes offer a middle ground ...

View MoreThe ideal tug of war rope length is usually between 33 and 36 meters (108–118 feet) for standard competitions. For casual games, schools, or backyard events, the rope length should be adjusted based on the number of play...

View MoreNylon vs Polyester Rope vs Polypropylene Rope: what changes in real use When customers ask me to compare nylon vs polyester rope vs polypropylene rope, they’re usually trying to avoid two expensive mistakes: picking a r...

View MoreBelow is a structured overview of common braided rope materials, their core properties, and typical applications. As a manufacturer, I ensure each batch is tested and certified to international standards—fast lead times with reliable consistency.

| Material | Key Properties | Typical Uses |

| Nylon Rope | High elasticity; excellent shock absorption; strong abrasion resistance | Anchor lines, towing, mooring, dynamic load handling |

| Polyester Rope | Low stretch; great UV & abrasion resistance; good wet strength | Rigging, static lines, outdoor lashing, winch lines |

| Polypropylene Rope | Lightweight; floats on water; economical; moderate strength | Water rescue throw lines, general utility, packaging |

| UHMWPE Rope | Ultra-high strength-to-weight; very low stretch; excellent chemical resistance | Winch replacement for steel, marine towing, high-performance rigging |

| Kevlar Rope | Exceptional heat resistance; high tensile strength; low elongation | Fire-resistant lines, high-temperature environments, cut-resistant applications |

We produce under ISO standards, test every batch, and I can organize fast delivery for both large and small orders.

| Usage Type | Recommended Material | Core Performance | Typical Notes |

| Safety Rope | Polyester sheath + polyester/UHMWPE core; optional aramid reinforcement | High strength, low elongation, abrasion and UV resistance | Often kernmantle; bright colors or reflective tracers for visibility; compliance testing available |

| Static Rope | Full polyester or polyester sheath with UHMWPE core | Low stretch, dimensional stability, durable sheath | Common diameters 8–11 mm for rigging, hauling, fixed systems |

| Water Rescue Rope | Polypropylene (PP) | Buoyant, low water absorption, high visibility | Throw-bag compatible; bright yellow/orange braids aid quick recovery |

| Parachute Cord (Paracord) | Nylon (multi-strand core + braided sheath) | Moderate stretch, strong yet pliable, reliable knotting | Type III 550 spec common; 4–7 inner strands; versatile outdoor utility |

| Gym Rope | Polyester or nylon (abrasion-focused jackets) | Grip-friendly texture, abrasion resistance, soft-hand feel | Typically 30–50 mm for battle ropes/climbing; textured surface enhances grip |

| Fireproof Rope | Kevlar (aramid) or heat-resistant blends | Thermal stability, minimal melt/drip, cut resistance | Aramid braids; optional protective coatings extend service life in hot work |

| Spring Twine | Polyester or polypropylene; elastic braid options | Lightweight, controlled elasticity and recovery | Ideal for packaging, gardening, general bundling; customizable elasticity and colors |

We export globally (U.S., Europe, Russia, U.K., South Korea, Japan), operate with 50+ machines over 5,600 m², and maintain comprehensive testing facilities. With flexible MOQs of 500–1,000 units, I can schedule production rapidly to meet your timeline without compromising quality.