This aramid rope is mainly used in high temperature operations, special ships, electrical engineerin...

Kevlar rope is made of high-strength Kevlar fiber, which has sound tensile resistance, high temperature resistance and wear resistance, as well as sound chemical corrosion resistance, and is suitable for high-intensity working environments.

It is light and flexible, and can be used in aerospace, military equipment, mountaineering rescue, industrial lifting and other fields, providing reliable safety protection and long service life.

Our Kevlar rope is made from DuPont's Kevlar material, offering exceptionally high strength, abrasion resistance, flame retardancy, aging resistance, and low elongation. It is suitable for firefighting, rescue operations, and high-temperature work environments.

This aramid rope is mainly used in high temperature operations, special ships, electrical engineerin...

Taizhou KA Protection Products Co., Ltd. is located in the Taizhou Economic Development Zone, Jiangsu Province, China, with convenient transportation.

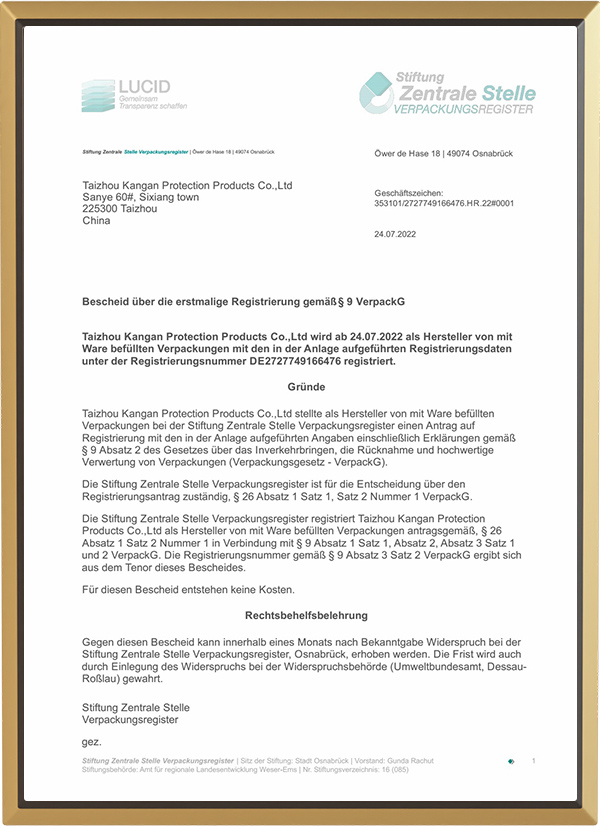

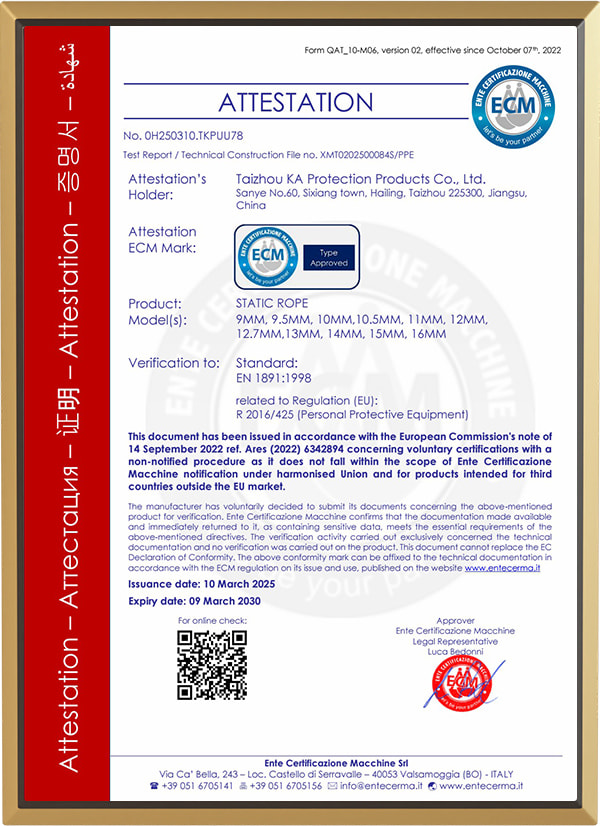

Since its establishment in 1986, the company has been dedicated to the production of safety harnesses, safety nets, safety ropes, and lifting slings. As OEM/ODM Kevlar Braided Rope Manufacturers and Kevlar Rope Company, our products are exported globally, including to countries such as the United States, Europe, Russia, the United Kingdom, South Korea, and Japan. Our products have undergone rigorous testing and have obtained international certifications, ensuring that each product provides crucial protection in critical moments.

The company's production strictly adheres to ISO standards, and each batch of products undergoes strict inspection to ensure quality. Supply Custom Braided Kevlar Cords, Kevlar Rope for sale. Currently, the company covers an area of 5,600 square meters and has a construction area of 3,800 square meters, equipped with over 50 pieces of production equipment and comprehensive testing facilities, focusing on delivering safety protection solutions to customers worldwide.

For most climbers, single ropes are the best choice for sport climbing and straightforward multi-pitch routes, while half ropes excel in wandering alpine terrain and mixed climbing, and twin ropes offer a middle ground ...

View MoreThe ideal tug of war rope length is usually between 33 and 36 meters (108–118 feet) for standard competitions. For casual games, schools, or backyard events, the rope length should be adjusted based on the number of play...

View MoreNylon vs Polyester Rope vs Polypropylene Rope: what changes in real use When customers ask me to compare nylon vs polyester rope vs polypropylene rope, they’re usually trying to avoid two expensive mistakes: picking a r...

View MoreBest Practices for Safe Use of Kevlar Rope: Load Ratings, Wear Indicators, and Replacement Rules

When it comes to high-performance applications, Kevlar rope stands out not just for its strength but for the critical role it plays in safety systems. Whether in rescue operations, industrial lifting, or military-grade environments, users rely on Kevlar’s exceptional durability and resistance to extreme conditions. But like any advanced material, getting the best out of a Kevlar braided rope isn't just about the product—it’s about how you use it. Designing effective safety protocols that include proper load rating management, inspection routines, and timely replacement criteria can significantly extend rope life and reduce operational risks.

Understanding load ratings is the first essential step. While Kevlar rope boasts a high tensile strength-to-weight ratio, using it without respecting its load specifications can lead to premature failure or unsafe conditions. Users should always consider the working load limit (WLL), which is typically a fraction of the rope’s actual breaking strength, to account for shock loads, dynamic movements, and environmental wear. When integrating braided Kevlar cord into critical systems, especially in vertical lifting or tension-bearing applications, accurate calculations and safety margins are non-negotiable.

Another often-overlooked factor is wear monitoring. Despite its resistance to abrasion and heat, Kevlar fiber can still degrade over time, especially at points of frequent friction or exposure to chemicals. Implementing visual inspection checkpoints—such as looking for surface fuzzing, discoloration, or flattening—helps identify early signs of wear. Unlike steel cables, Kevlar does not exhibit catastrophic snapping under load, but it can lose performance subtly, making routine assessments even more important. Keeping logs of usage duration and stress conditions can help maintenance teams make data-driven decisions.

For long-term safety, replacement schedules are just as critical. Braided Kevlar ropes used in dynamic or high-risk environments shouldn't be run to failure. Manufacturers often suggest replacement intervals based on hours of use or environmental exposure levels, but these should be adapted to the specific application. In firefighting or hot-zone rescue tasks, for example, a rope may need replacing more frequently than in a static load-bearing setup. It's not just about visible damage—thermal aging or micro-abrasion can gradually weaken fiber integrity without immediate signs.

Many users make the mistake of storing Kevlar products improperly, shortening their service life. The rope should be kept away from UV exposure, sharp objects, and chemical residues. Using protective sleeves or integrating the rope into systems that minimize sharp bends can also help preserve its load-bearing capabilities. For those working in environments where contamination or fluid exposure is possible, choosing a Kevlar braided rope with protective coatings can provide an extra layer of assurance.

As a manufacturer with years of experience in technical fiber applications, we’ve worked closely with industries that demand absolute performance—from aerospace teams to energy contractors. Our Kevlar rope products are built with DuPont’s original material and manufactured under stringent quality control to ensure consistency and reliability. Whether you're designing a high-tension hoisting system or outfitting a rescue unit, working with a supplier who understands the operational realities behind the product can make a real difference.