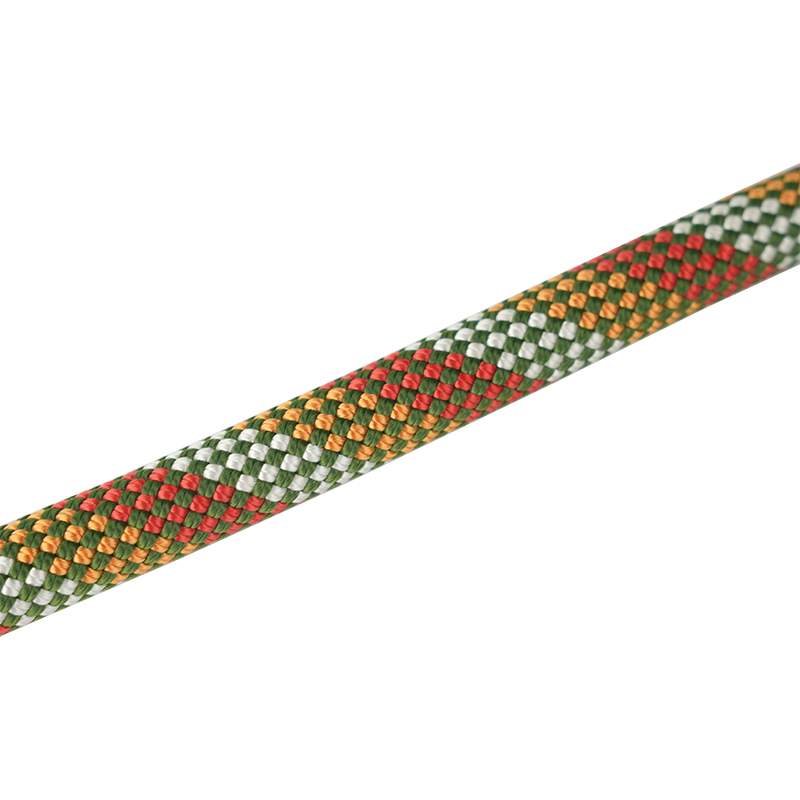

The inner core and outer skin of the 10mm 2200kgs nylon braided rope fit very well, and the feel is ...

Nylon rope is a rope made of nylon material. It is a thermoplastic resin with good flexibility, impact resistance, wear resistance, UV resistance, corrosion resistance, high strength and good toughness.

The prominent advantage of polyamide fiber is its sound wear resistance compared to other fibers, followed by its good elasticity, its elastic recovery rate is comparable to wool, and its light weight, with a specific gravity of 1.14. Among the commercialized synthetic fibers, it is second only to polypropylene (polypropylene specific gravity is less than 1), and lighter than polyester fiber (specific gravity 1.38).

Nylon rope is widely used in various industries, including electricity, metallurgy, petroleum, machinery, railways, chemicals, ports, mines and construction. Because it is light, fast, wear-resistant and does not produce sparks, nylon rope is an ideal substitute for steel wire rope, especially suitable for hoisting operations that do not damage the surface paint.

The inner core and outer skin of the 10mm 2200kgs nylon braided rope fit very well, and the feel is ...

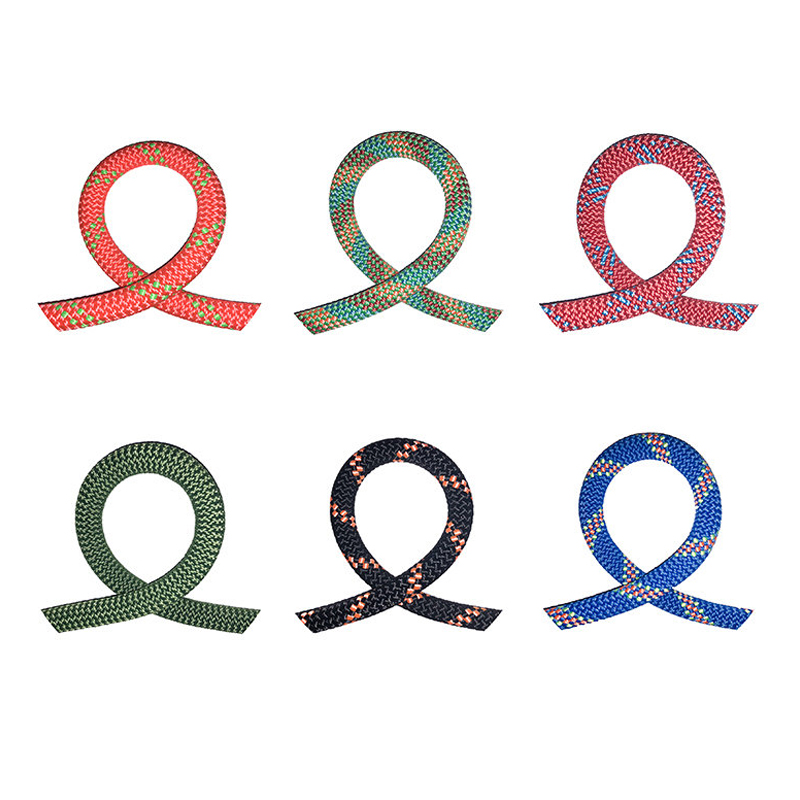

This 8mm wireless colorful nylon rope is crafted from premium nylon, combining high strength with ...

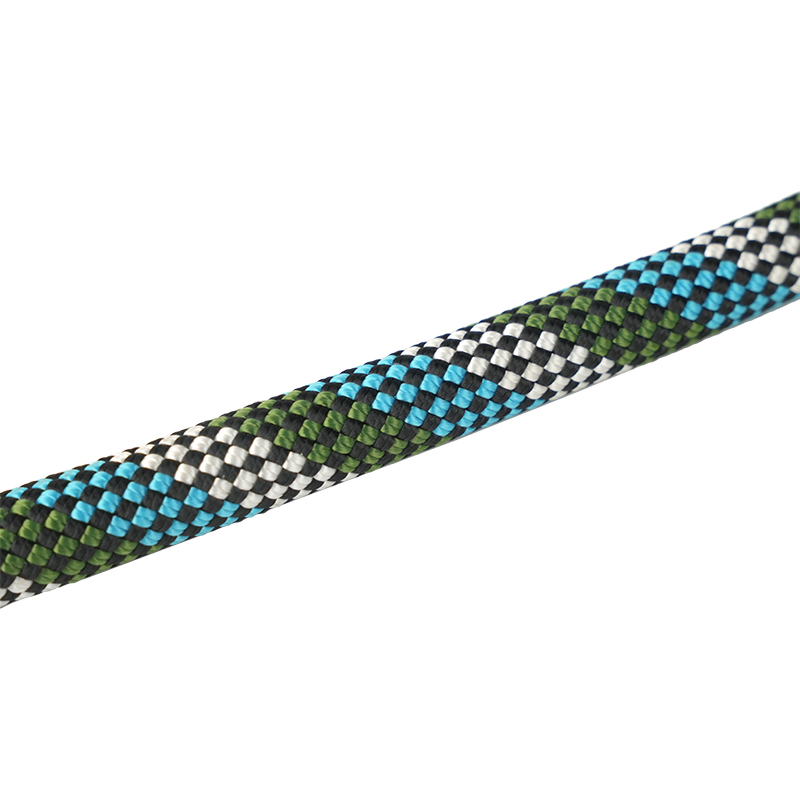

Crafted from high-strength nylon, this 12mm diameter rope is engineered for heavy-duty and complex e...

Taizhou KA Protection Products Co., Ltd. is located in the Taizhou Economic Development Zone, Jiangsu Province, China, with convenient transportation.

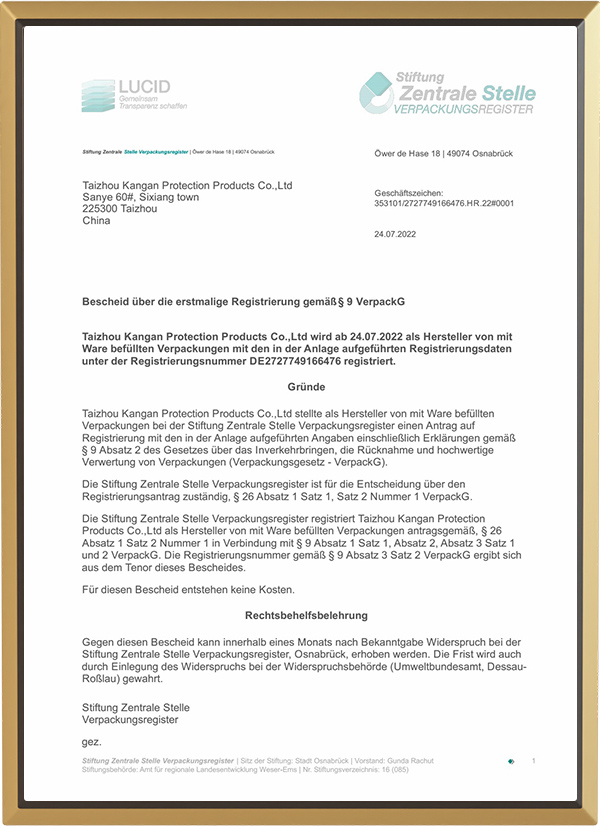

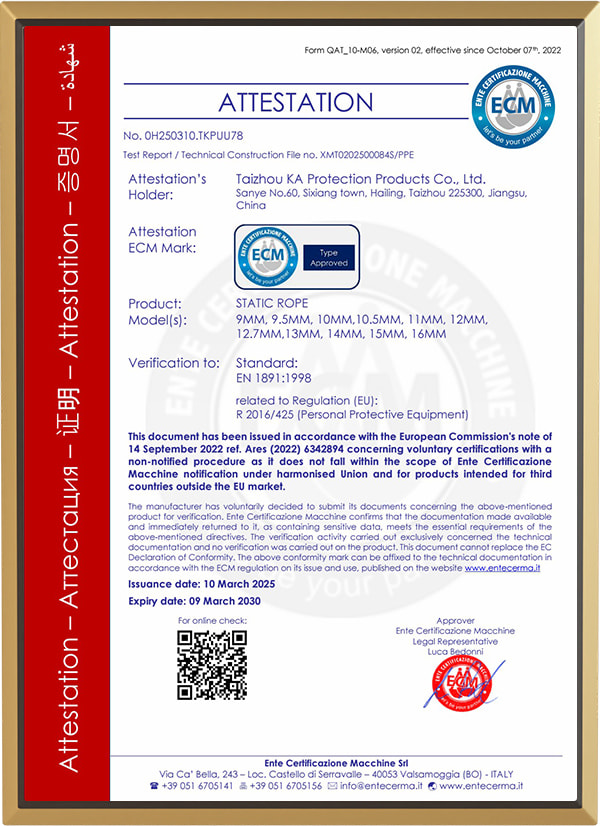

Since its establishment in 1986, the company has been dedicated to the production of safety harnesses, safety nets, safety ropes, and lifting slings. As OEM/ODM Braided Nylon Rope Manufacturers and Nylon Rope Company, our products are exported globally, including to countries such as the United States, Europe, Russia, the United Kingdom, South Korea, and Japan. Our products have undergone rigorous testing and have obtained international certifications, ensuring that each product provides crucial protection in critical moments.

The company's production strictly adheres to ISO standards, and each batch of products undergoes strict inspection to ensure quality. Supply Custom Braided Nylon Ropes, Nylon Ropes For sale. Currently, the company covers an area of 5,600 square meters and has a construction area of 3,800 square meters, equipped with over 50 pieces of production equipment and comprehensive testing facilities, focusing on delivering safety protection solutions to customers worldwide.

For most climbers, single ropes are the best choice for sport climbing and straightforward multi-pitch routes, while half ropes excel in wandering alpine terrain and mixed climbing, and twin ropes offer a middle ground ...

View MoreThe ideal tug of war rope length is usually between 33 and 36 meters (108–118 feet) for standard competitions. For casual games, schools, or backyard events, the rope length should be adjusted based on the number of play...

View MoreNylon vs Polyester Rope vs Polypropylene Rope: what changes in real use When customers ask me to compare nylon vs polyester rope vs polypropylene rope, they’re usually trying to avoid two expensive mistakes: picking a r...

View MoreUnderstanding Nylon Rope Under Load: How It Performs, Stretches, and Recovers in Real-World Use

When it comes to choosing materials for lifting, towing, or securing in industrial environments, understanding how a rope behaves under load is critical. Nylon rope, known for its toughness and reliability, offers distinct mechanical characteristics that make it stand out in performance-driven applications. One of its most important properties is its elasticity—the ability to stretch and recover—which directly influences shock absorption, load distribution, and long-term durability during use.

Unlike stiffer materials, nylon exhibits significant elongation under tension. This means when a load is applied, especially a sudden one, the rope stretches to absorb part of the force, reducing the risk of sudden breakage or damage to connected equipment. This trait is particularly valued in operations like crane rigging or marine towing, where variable forces are common. For users handling dynamic loads, such as in railways or construction sites, this “give” can be the difference between safe operation and system failure.

Equally important is the rope's recovery capability. Once the tension is released, a properly engineered nylon rope, including types like braided nylon rope, returns close to its original length without permanent deformation. This elastic recovery is not just about shape—it directly impacts the lifespan of the rope. Repeated loading and unloading cycles become less damaging over time, giving nylon a cost-effective edge in operations where ropes are constantly in motion or exposed to vibration and shock.

It’s worth noting that not all nylon ropes behave identically. Variables like rope diameter, strand count, and whether the rope is twisted or braided affect how it handles under strain. Braided nylon rope, for example, generally offers better flexibility and smoother handling, which enhances both performance and user safety in more refined mechanical settings. On the other hand, some heavy-duty applications might prefer the slightly stiffer response of thicker, multi-strand constructions.

Environmental conditions also play a role in how nylon rope performs under load. High humidity, submersion, or exposure to chemicals may affect its elasticity slightly, though nylon is more resistant than many synthetic fibers in these respects. Its ability to perform across such a wide range of conditions has led to its widespread adoption across industries like ports, mining, and heavy machinery handling, where reliability can’t be compromised.

As a manufacturer and supplier with deep experience in industrial rope solutions, we’ve seen firsthand how understanding the mechanical behavior of nylon rope under real-world stress can guide better purchasing and safer usage. Choosing the right construction, diameter, and finish isn’t just a technical decision—it’s a business investment in durability, safety, and performance. Our nylon ropes are designed with these practical needs in mind, backed by quality control and customization options to fit your operation precisely.