Material: polypropyleneDiameter: 10mmWeaving process: 48-strand diamond weavingInner core: multipl...

Polypropylene is a semi-crystalline thermoplastic polymer made from propylene monomers through addition polymerization. It is non-toxic, odorless, light in texture, with a density of 0.89-0.92 g/cm3, which is the density of thermoplastic resin; the melting point is 164-176 ℃, softening at around 155 ℃, and the use temperature range is -30-140 ℃. Polypropylene is light, wear-resistant, antibacterial, easy to dye, insulating, chemically stable, heat-resistant, corrosion-resistant, weather-resistant, and plastic. It is particularly suitable for seawater operations, packaging, water rescue, etc.

Material: polypropyleneDiameter: 10mmWeaving process: 48-strand diamond weavingInner core: multipl...

12mm Lightweight Buoyant Polypropylene Braided Rope is made of high-quality polypropylene (PP) and i...

The 8mm white polypropylene braided rope is made of polypropylene (PP) and has high strength and wea...

Taizhou KA Protection Products Co., Ltd. is located in the Taizhou Economic Development Zone, Jiangsu Province, China, with convenient transportation.

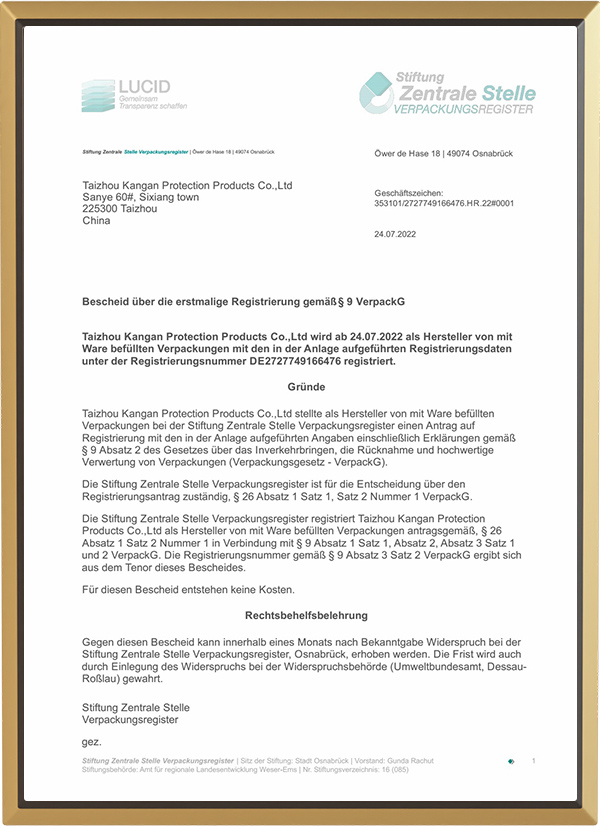

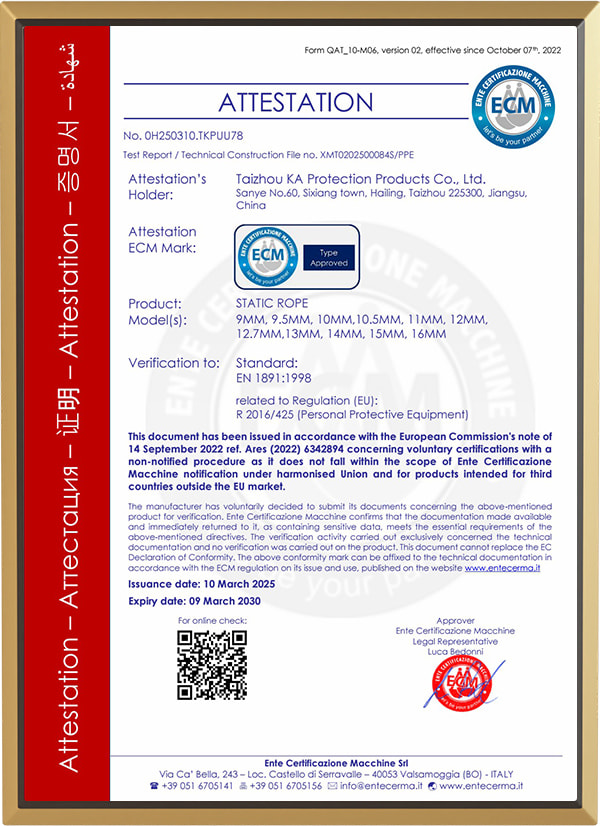

Since its establishment in 1986, the company has been dedicated to the production of safety harnesses, safety nets, safety ropes, and lifting slings. As OEM/ODM PP Rope Manufacturers and Braid Polypropylene Rope Company, our products are exported globally, including to countries such as the United States, Europe, Russia, the United Kingdom, South Korea, and Japan. Our products have undergone rigorous testing and have obtained international certifications, ensuring that each product provides crucial protection in critical moments.

The company's production strictly adheres to ISO standards, and each batch of products undergoes strict inspection to ensure quality. Supply Custom Polypropylene Rope, PP Braided Rope for sale. Currently, the company covers an area of 5,600 square meters and has a construction area of 3,800 square meters, equipped with over 50 pieces of production equipment and comprehensive testing facilities, focusing on delivering safety protection solutions to customers worldwide.

For most climbers, single ropes are the best choice for sport climbing and straightforward multi-pitch routes, while half ropes excel in wandering alpine terrain and mixed climbing, and twin ropes offer a middle ground ...

View MoreThe ideal tug of war rope length is usually between 33 and 36 meters (108–118 feet) for standard competitions. For casual games, schools, or backyard events, the rope length should be adjusted based on the number of play...

View MoreNylon vs Polyester Rope vs Polypropylene Rope: what changes in real use When customers ask me to compare nylon vs polyester rope vs polypropylene rope, they’re usually trying to avoid two expensive mistakes: picking a r...

View MoreWhy Polypropylene Rope Outperforms Other Plastics in Demanding Marine and Coastal Environments

When it comes to materials used in marine and coastal environments, the selection must go far beyond basic durability. Saltwater corrosion, constant UV exposure, and physical stress make these environments particularly challenging for most plastics. Among available options, polypropylene—commonly used in products like PP rope and PP braided rope—has proven to be one of the most reliable choices. Its molecular composition and inherent properties offer a unique advantage that outperforms alternatives like PVC, nylon, and polyethylene in these conditions.

One of the key reasons polypropylene rope stands out is its excellent resistance to chemical degradation, particularly in saline conditions. Unlike nylon, which can absorb water and weaken over time, or PVC, which may harden and crack under long-term sun exposure, polypropylene maintains its integrity. This makes it particularly well-suited for applications such as mooring lines, towing equipment, and emergency rescue systems where performance cannot be compromised. Its non-absorbent nature ensures that a braid polypropylene rope retains strength and buoyancy even after prolonged contact with seawater.

Speaking of buoyancy, this is another area where polypropylene-based ropes outperform many competitors. The low density of polypropylene—approximately 0.91 g/cm³—means it naturally floats. This property is not only useful for ease of retrieval but also adds a safety advantage in rescue scenarios, where visibility and quick access matter. Other thermoplastics may offer decent tensile strength, but they often sink or become heavy when wet, which limits their practicality in certain applications. This is one of the reasons why commercial users consistently turn to Polypropylene rope for demanding water-based tasks.

UV resistance also plays a critical role. Polypropylene, when properly stabilized, shows strong resistance to UV-induced degradation. Over time, sun exposure can cause many materials to become brittle or lose tensile strength, but modern formulations of PP rope are often treated with UV inhibitors to significantly extend their service life. This allows for reliable performance in both tropical and temperate climates, making it a trusted material for coastal infrastructure, fishing gear, and port handling systems where ropes are constantly exposed to direct sunlight.

Another important consideration is wear resistance and flexibility. Polypropylene ropes are valued for their balance between strength and handling comfort. In braided forms, such as PP braided rope, the texture is smoother, reducing friction and making them easier to grip and knot without sacrificing durability. These mechanical properties are especially beneficial in dynamic environments where the rope is subject to repeated stress, bending, and abrasion. This balance of strength and usability helps reduce replacement frequency, lowering operational costs over time.

From a manufacturer’s perspective, one of the standout advantages is the adaptability of polypropylene to various processing methods and design requirements. Whether it’s customizing the diameter, color-coding for identification, or integrating floating markers, PP rope products can be tailored to suit specific client needs. This versatility, coupled with cost-efficiency, makes polypropylene a highly scalable solution for industrial users who demand both performance and reliability without unnecessary expense. That’s why we continue to recommend our range of braid polypropylene rope solutions to clients across maritime, logistics, and rescue sectors.