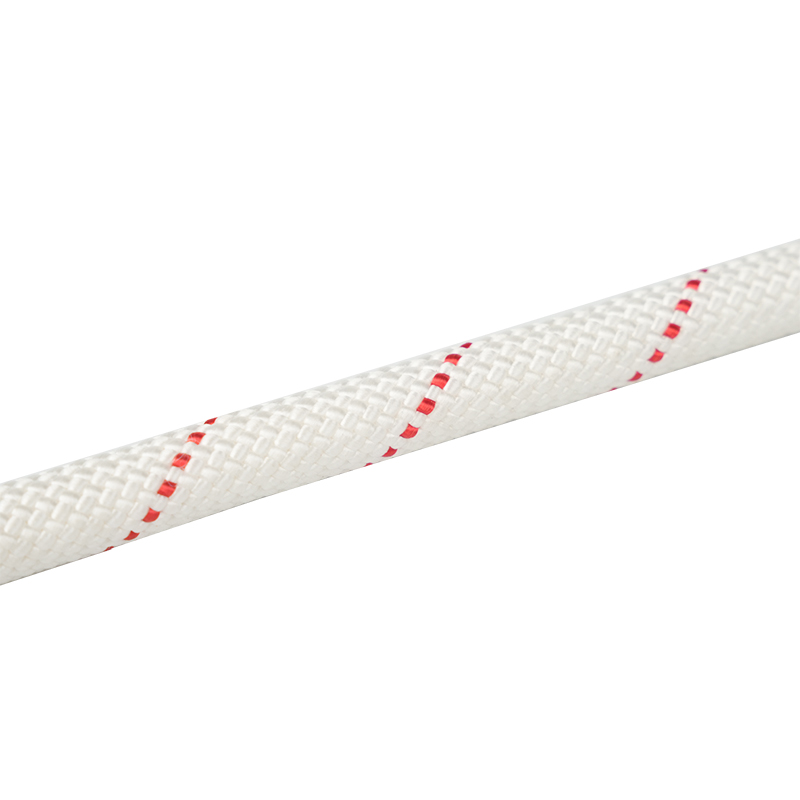

This 10mm UHMWPE rope is highly strong and performs well. It can be used for water rescue, seawater ...

Ultra-high molecular weight polyethylene is an unbranched linear polyethylene with a molecular weight of more than 1.5 million. Density: 0.920-0.964g/cm3. Heat deformation temperature (0.46MPa) 85℃, melting point 130-136℃. The surface is flat, uniform, and smooth, and the cross-sectional density is very uniform. It is the third generation of special fiber in the world today, with a strength of up to 30.8cN/dtex, the specific strength among chemical fibers, and good wear resistance, impact resistance, corrosion resistance, light resistance, and other properties. It can be directly made into ropes, cables, fishing nets, etc. Internationally, ultra-high molecular weight polyethylene fibers have been woven into ropes of different deniers, replacing traditional steel cables and synthetic fiber ropes. The strength of ultra-high molecular weight polyethylene is 3 times that of nylon, and the wear resistance is 2 times that of nylon. It is suitable for water rescue, lifting, protection, ships, etc.; the striking performance of ultra-high molecular weight polyethylene is that it has extremely high wear resistance and extremely high impact resistance.

This 10mm UHMWPE rope is highly strong and performs well. It can be used for water rescue, seawater ...

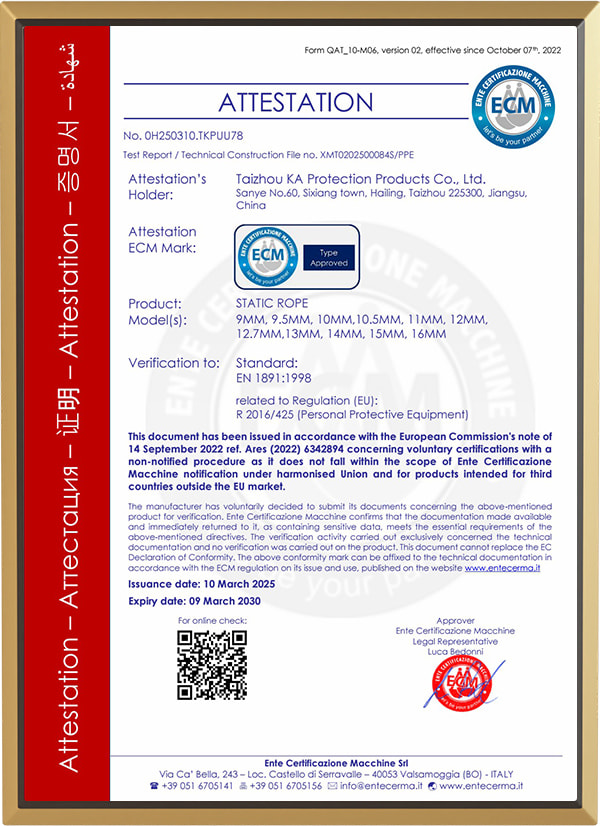

Taizhou KA Protection Products Co., Ltd. is located in the Taizhou Economic Development Zone, Jiangsu Province, China, with convenient transportation.

Since its establishment in 1986, the company has been dedicated to the production of safety harnesses, safety nets, safety ropes, and lifting slings. As OEM/ODM UHMWPE Rope Manufacturers and Ultra High Molecular Weight Polyethylene Rope Company, our products are exported globally, including to countries such as the United States, Europe, Russia, the United Kingdom, South Korea, and Japan. Our products have undergone rigorous testing and have obtained international certifications, ensuring that each product provides crucial protection in critical moments.

The company's production strictly adheres to ISO standards, and each batch of products undergoes strict inspection to ensure quality. Supply Custom UHMWPE Rope, Ultra High Molecular Weight Polyethylene Rope for sale. Currently, the company covers an area of 5,600 square meters and has a construction area of 3,800 square meters, equipped with over 50 pieces of production equipment and comprehensive testing facilities, focusing on delivering safety protection solutions to customers worldwide.

For most climbers, single ropes are the best choice for sport climbing and straightforward multi-pitch routes, while half ropes excel in wandering alpine terrain and mixed climbing, and twin ropes offer a middle ground ...

View MoreThe ideal tug of war rope length is usually between 33 and 36 meters (108–118 feet) for standard competitions. For casual games, schools, or backyard events, the rope length should be adjusted based on the number of play...

View MoreNylon vs Polyester Rope vs Polypropylene Rope: what changes in real use When customers ask me to compare nylon vs polyester rope vs polypropylene rope, they’re usually trying to avoid two expensive mistakes: picking a r...

View MoreHow Molecular Weight Shapes the Strength and Performance of Ultra High Molecular Weight Polyethylene Rope

When people first hear about ultra high molecular weight polyethylene (UHMWPE) rope, what usually grabs their attention is the outstanding mechanical performance—especially in comparison to traditional rope materials like PP rope or even nylon. But behind the strength and durability lies something less visible but fundamentally important: molecular weight. In UHMWPE, molecular weight isn’t just a number—it directly influences performance in ways that determine how well the material holds up under pressure, abrasion, and impact.

Molecular weight refers to the length and entanglement of polymer chains. In UHMWPE, this weight exceeds 1.5 million, sometimes reaching up to 6 million g/mol. This incredibly high value results in a tightly entangled structure, giving the material its signature strength and wear resistance. For example, UHMWPE rope made with these extended chains demonstrates tensile strength far superior to most conventional synthetic fibers. That’s why industries working in critical load-bearing environments—like offshore lifting, winching, or defense—often prefer UHMWPE over other rope materials.

Compared with something like PP rope, which is valued for affordability and lightweight properties, UHMWPE brings a different value proposition: long-term performance in extreme conditions. While PP ropes may be suitable for light-duty or short-term applications, UHMWPE ropes are trusted in demanding environments precisely because their molecular structure helps prevent elongation, fraying, and fatigue. This makes them ideal for marine use, industrial rigging, and rescue scenarios, where reliability matters as much as initial cost.

Another key benefit linked to molecular weight is impact resistance. The longer the polymer chains, the more energy the material can absorb without breaking. That’s why ultra high molecular weight polyethylene rope doesn’t just perform better in static strength tests—it also holds up under dynamic loads and sudden impacts. From years of manufacturing experience, we’ve seen that end users consistently report lower replacement rates and improved operational safety when switching from lower-grade synthetics to high-molecular-weight polyethylene rope solutions.

The flip side of this robust structure is that processing UHMWPE can be more challenging. Its viscosity is so high in molten form that conventional extrusion or molding techniques don’t apply. That’s where specialized equipment and technical know-how come in—something a reliable manufacturer should be equipped with. By optimizing molecular weight for each rope application and using precision processing techniques, we ensure consistent product performance that matches real-world industrial demands.

For buyers looking to upgrade their rope systems, understanding the impact of molecular weight on durability and strength can guide smarter sourcing decisions. Whether you're looking to improve safety margins in your lifting operations or reduce downtime from wear-related rope failure, UHMWPE rope offers a practical, long-lasting solution. It’s not just about raw performance—it’s about confidence in your equipment. And when that equipment is built on decades of molecular engineering, it shows in the results.

If your business is seeking a reliable supplier of high-performance rope solutions, we offer UHMWPE ropes crafted to exacting standards for strength, wear resistance, and long-term durability. With proven experience in export and industrial applications, our goal is to help you find the right material fit—so you can focus on performance, not replacement.