This safety rope is sound when working with heights plus it is a low stretch rope. Its diameter is ...

The safety rope is woven from synthetic fibers and is an auxiliary rope used to connect the safety belt. Its function is double protection to ensure safety.

The uses of safety ropes are generally divided into two categories. One is platform operations with an angle of no more than 15 degrees and a strength of more than 1500kg. The other is vertical operations with a strength of more than 2200kg.

The diameter of the safety rope is usually 10mm~16mm, and the length used for platform operations is generally 3 meters, 5 meters, 10 meters and 15 meters or longer. The length used for vertical operations is no more than 2 meters.

Commonly used safety ropes are generally made of polyester, nylon, etc.; live operation safety ropes are generally made of ultra-high molecular weight polyethylene, Kevlar, etc.; ultra-high strength safety ropes are generally made of ultra-high molecular weight polyethylene, Kevlar, etc.;

The safety rope has a soft feel, good wear resistance, corrosion resistance, high temperature resistance, and strong selectivity.

This safety rope is sound when working with heights plus it is a low stretch rope. Its diameter is ...

The 13mm polyester safety rope is made of high-strength polyester fibers, offering low-stretch prope...

The 12mm diameter nylon safety rope is known for its soft texture and ease of handling, making it su...

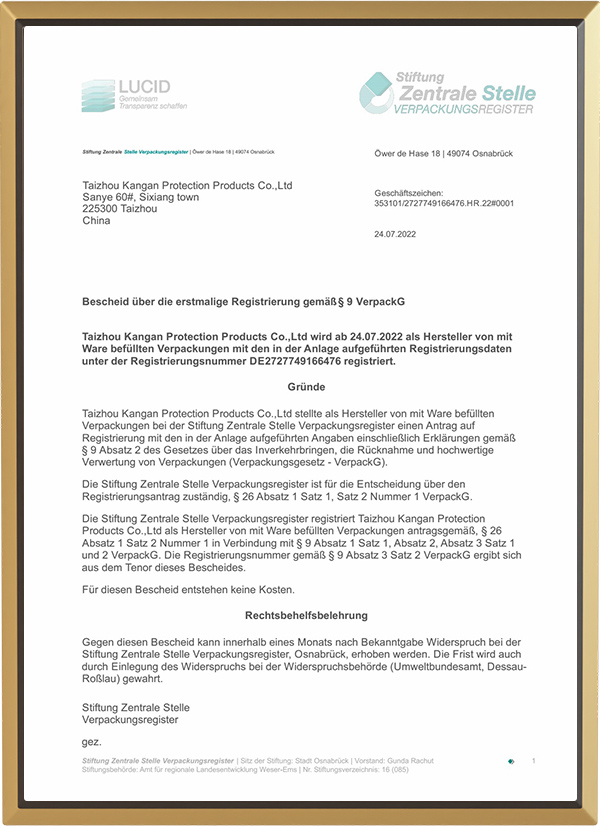

Taizhou KA Protection Products Co., Ltd. is located in the Taizhou Economic Development Zone, Jiangsu Province, China, with convenient transportation.

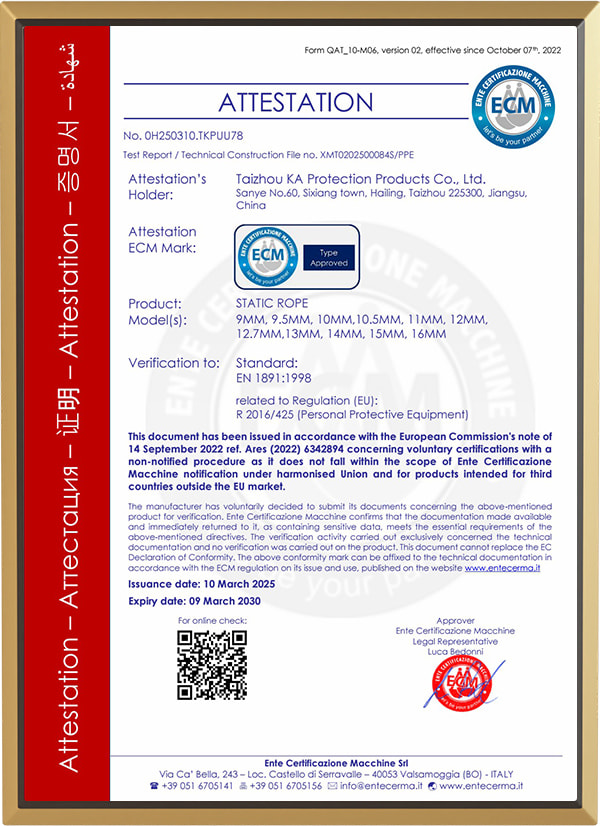

Since its establishment in 1986, the company has been dedicated to the production of safety harnesses, safety nets, safety ropes, and lifting slings. As OEM/ODM Safety Rope Manufacturers and Fall Arrest Rope Company, our products are exported globally, including to countries such as the United States, Europe, Russia, the United Kingdom, South Korea, and Japan. Our products have undergone rigorous testing and have obtained international certifications, ensuring that each product provides crucial protection in critical moments.

The company's production strictly adheres to ISO standards, and each batch of products undergoes strict inspection to ensure quality. Supply Customized Fall Protection Safety Rope, Fall Arrest Rope for sale. Currently, the company covers an area of 5,600 square meters and has a construction area of 3,800 square meters, equipped with over 50 pieces of production equipment and comprehensive testing facilities, focusing on delivering safety protection solutions to customers worldwide.

For most climbers, single ropes are the best choice for sport climbing and straightforward multi-pitch routes, while half ropes excel in wandering alpine terrain and mixed climbing, and twin ropes offer a middle ground ...

View MoreThe ideal tug of war rope length is usually between 33 and 36 meters (108–118 feet) for standard competitions. For casual games, schools, or backyard events, the rope length should be adjusted based on the number of play...

View MoreNylon vs Polyester Rope vs Polypropylene Rope: what changes in real use When customers ask me to compare nylon vs polyester rope vs polypropylene rope, they’re usually trying to avoid two expensive mistakes: picking a r...

View MoreUnderstanding Braiding Structures: How Rope Engineering Shapes Fall Protection Safety Rope Performance

When it comes to choosing a reliable safety rope for industrial or construction applications, few aspects are as technically decisive yet often overlooked as the rope’s braiding structure. While material selection naturally draws much attention, the engineering behind how the rope is woven plays a critical role in determining its strength, flexibility, durability, and ease of use. For manufacturers like us with years of experience in the production and export of fall protection safety rope, understanding the practical impacts of braiding designs is essential to delivering both safety and performance in real working conditions.

One of the most commonly used braiding styles in the industry is the kernmantle structure, which features a load-bearing core (kern) protected by a braided outer sheath (mantle). This design is widely adopted in fall arrest rope products due to its excellent balance between strength and handling. The core provides most of the tensile strength, while the sheath offers abrasion resistance and shields the inner fibers from environmental exposure. This dual-layer configuration not only extends the rope’s working life but also ensures stable performance under dynamic load conditions, such as during a sudden fall.

In comparison, twisted ropes—often found in lower-cost or older systems—offer less resistance to abrasion and can more easily unravel or deform under stress. While suitable for certain basic utility tasks, twisted ropes generally fall short when it comes to meeting the rigorous demands of fall protection systems. That’s why premium safety ropes, especially those used in vertical rescue or tower climbing scenarios, tend to use kernmantle or double-braided constructions. Double-braiding, where both core and sheath are braided, adds another layer of durability and is often preferred for tasks requiring repeated use or exposure to high friction.

The choice of braiding also affects how the rope behaves in the hands of the worker. A well-braided rope has a smooth, uniform surface that ensures predictable grip and minimizes internal slippage, which is especially critical when working with mechanical devices like descenders or ascenders. Consistency in diameter and flexibility, resulting from high-quality braiding techniques, also improves knotting performance and compatibility with standard rope hardware. This level of performance detail often makes the difference between a rope that merely meets specifications and one that earns the trust of field professionals.

Additionally, modern manufacturing techniques allow for more precise braiding tension and fiber alignment, reducing internal wear and improving resistance to deformation over time. These advances translate into real-world benefits for companies seeking dependable fall protection solutions—fewer replacements, lower maintenance costs, and improved worker safety. As a manufacturer, we incorporate these methods not as extras but as a core part of our product philosophy, because we know that every detail matters when it comes to fall prevention.

Another practical consideration is visibility and inspection. Braiding patterns can be engineered to include colored tracer threads or wear indicators, making it easier for users to detect damage or degradation. Some high-performance ropes even integrate reflective yarns for low-light environments. This not only enhances safety but supports compliance with inspection protocols, especially in industries like energy, telecom, and offshore operations, where documentation and accountability are non-negotiable.

Ultimately, investing in the right braiding structure means investing in long-term performance, safety, and operational confidence. Whether you're sourcing a fall protection safety rope for new projects or replacing aging fall arrest ropes, understanding the structural integrity behind the weave can help you make more informed and cost-effective decisions. As a professional safety rope supplier and exporter, we're here not just to sell a product, but to offer a solution built on expertise, engineering, and real-world insight.